You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm RCBS 82150 145 SIL-GC makes bullets with noses too big

- Thread starter Wallyl

- Start date

Glad that we agree. Others mention getting a mold that makes better fitting bullets...a great idea, but each rifle is a bit different and the only solution for the perfect fit is to have a custom mold that makes bullets that exactly fit your rifle barrel. All I want to do is hit 3.5" oil filters at 200 yards and I'm good...I am not a member of the sub-moa crowd (they threw me out). .

SWISS SHOOTER

Banned

A correct mold casts 90 bucks. All the screwing around with nose sizers etc etc will eat up more than that in time and effort.

A correct mold casts 90 bucks. All the screwing around with nose sizers etc etc will eat up more than that in time and effort.

If that's not your thing I highly recommend your not doing it. Many people thoroughly enjoy the tinkering and experimentation including the quest for higher velocity, me included.

No one is wrong for experimenting, no one is wrong for not experimenting. Everyone is happy. See how easy that is?

Ian

Notorious member

And I'm happy spending an hour or two with my lathe making a custom die.

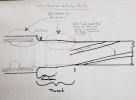

Here's one that puts a throat matching funnel shape on the noses and sizes the body to .310" at the same time. Left is sized, right is unsized. Fits my M1A perfectly and bullet fit is very important for a semi-automatic rifle:

Here's one that puts a throat matching funnel shape on the noses and sizes the body to .310" at the same time. Left is sized, right is unsized. Fits my M1A perfectly and bullet fit is very important for a semi-automatic rifle:

Last edited:

Bret4207

At the casting bench in the sky. RIP Bret.

As I said, maybe some people don't have money to burn. Altering an alloy is a pretty inexpensive way of making a mould fit like you want. The is no one right answer. For some people a custom mould would be the first choice, the only choice even. For others $90.00 might be a major expense that they can't justify.A correct mold casts 90 bucks. All the screwing around with nose sizers etc etc will eat up more than that in time and effort.

To each their own.

SWISS SHOOTER

Banned

You can "justify" 1000s for guns and reloading equipment but a 90 buck mold is beyond you ?

Gimme a break. There is the easy way and the hard way. I prefer the former.

All done with this thread as it's going nowhere.

Gimme a break. There is the easy way and the hard way. I prefer the former.

All done with this thread as it's going nowhere.

RBHarter

West Central AR

I have a significant investment in AA&E . I'd guess I have had maybe 5 of 80 or so that were valued over 500 dollars , most were well under 300 .

I bought a purpose cut mould once , several NOEs , even a brass M-P . I do have a just barely enough Lyman and an undersized RCBS .

Sure I have a bunch invested in it but nowhere near full retail ......

I refuse to spend more on a new car than my house .......for which we paid 38% of the previous sale . They say cheapness is not greatness . It sure makes the money last longer .

I bought a purpose cut mould once , several NOEs , even a brass M-P . I do have a just barely enough Lyman and an undersized RCBS .

Sure I have a bunch invested in it but nowhere near full retail ......

I refuse to spend more on a new car than my house .......for which we paid 38% of the previous sale . They say cheapness is not greatness . It sure makes the money last longer .

I don’t think 90 bucks has anything to do with it, I think it’s about making shit work that ain’t supposed too. I mean if we, and I mean casters and handloaders in general are tinkerers by default, if you don’t like tinkering with this or that it’s the wrong hobby, In my opinion anyway. Either way I’ve got molds that have yet to cast a bullet because it is a project I have down the line. So another mold or two doesn’t matter to me much in the grand scheme of things, but to the fella who has other expenses and is trying to get by, a 2 cavity Lee mold may be all they are able to afford, and out of necessity need it too work. I mean look around and see if you find any factory ammo.

Either way, if you have the time and means, why not make a custom sizing die to perfectly fit a bullet to your rifle? Makes perfect sense to me.

As far as the original post is concerned from all accounts that RCBS 7mm-145 SIL is one hell of a bullet for everyone that gives it a chance. It is actually going to be used in my little 7mm-08 project I’ve got on hold due to I have very little brass on hand. Gave all my 7-08 away a few years back before I had one of my own. But I have a couple hundred checked and coated and ready for there final sizing. Which speaking of, they should be aged out good right about now. May need to find some brass. Time to do a good cleaning and a pound cast.

Oh the list just gets longer.

Either way, if you have the time and means, why not make a custom sizing die to perfectly fit a bullet to your rifle? Makes perfect sense to me.

As far as the original post is concerned from all accounts that RCBS 7mm-145 SIL is one hell of a bullet for everyone that gives it a chance. It is actually going to be used in my little 7mm-08 project I’ve got on hold due to I have very little brass on hand. Gave all my 7-08 away a few years back before I had one of my own. But I have a couple hundred checked and coated and ready for there final sizing. Which speaking of, they should be aged out good right about now. May need to find some brass. Time to do a good cleaning and a pound cast.

Oh the list just gets longer.

fiver

Well-Known Member

you could just buy a 7 dollar can of mold release tape off half the mold and paint the nose of the mold smaller easy enough.

the shipping would probably cost 83 bucks so your back to the 90 dollar price again.

BTW.

that 90 bucks is more than half of my monthly allowance.

if i buy a 90 dollar mold that equals 2.5 trap shooting trips, 3 bass fishing trips with the boat,

7-8 deer/elk/grouse days, or 6 trout fishing trips from the bank.

i have to pretty much pick and choose from those things each month this time of year [except the bass trips the boat ain't coming out from it's cover till spring] and do nothing else the rest of the month.

the shipping would probably cost 83 bucks so your back to the 90 dollar price again.

BTW.

that 90 bucks is more than half of my monthly allowance.

if i buy a 90 dollar mold that equals 2.5 trap shooting trips, 3 bass fishing trips with the boat,

7-8 deer/elk/grouse days, or 6 trout fishing trips from the bank.

i have to pretty much pick and choose from those things each month this time of year [except the bass trips the boat ain't coming out from it's cover till spring] and do nothing else the rest of the month.

I’ve thought about it. I’ve got a good bit of 308 I also have a bunch of 308s too, but I have thought about digging out 50 matched cases and necking down to 7mm, if I can’t find some 7mm-08 at a decent price by first of the year I’ll be necking some down 308 brass is easy enough to replace.

You actually have talked me into it while I’m sitting here typing this. 50 cases can be done in a couple of hours while enjoying a few adult beverages.

You actually have talked me into it while I’m sitting here typing this. 50 cases can be done in a couple of hours while enjoying a few adult beverages.

fiver

Well-Known Member

i can go carp/cat fishing everyday of the month for free if i wanna, dig worms and walk the mile down to the lake.

in a couple more years i can go down to the little lake err 100'x100' stocked marsh pond 3 blocks away, till then i gotta drive the 20 miles to one of the 2 lakes just north of here.

never caught a fish in one of them so i ignore it and fish the further away one.

not much sense taking the boat since i know the good spots and how to fish them on the second, and if i do take the boat i usually end up in one of them anyway.

in a couple more years i can go down to the little lake err 100'x100' stocked marsh pond 3 blocks away, till then i gotta drive the 20 miles to one of the 2 lakes just north of here.

never caught a fish in one of them so i ignore it and fish the further away one.

not much sense taking the boat since i know the good spots and how to fish them on the second, and if i do take the boat i usually end up in one of them anyway.

Bret4207

At the casting bench in the sky. RIP Bret.

This thread is going just fine. It all comes down to each of us accepting others have different priorities, limits and what ends up being the answer we go with.

FWIW- I've never ordered a high buck mould. The most I ever paid was $75.00 for a 10 cav H+G with handles and I about crapped myself doing it. Most of my moulds came in at the $15-25 range. Same for my presses, powder measures, dies, etc. I've bought one new gun in my life. Most are very well used and I've never paid more than $450. IIRC, and that was for a Lew Horton Smith 24-3 with the Horton holster. Same with scopes, most I ever paid was $150 for a period correct Lyman Jr Targetspot for my 52 Winchester- which I paid $5.00 for. Yes, $5.00.

So yeah, $90.00 is a significant amount to some of us.

FWIW- I've never ordered a high buck mould. The most I ever paid was $75.00 for a 10 cav H+G with handles and I about crapped myself doing it. Most of my moulds came in at the $15-25 range. Same for my presses, powder measures, dies, etc. I've bought one new gun in my life. Most are very well used and I've never paid more than $450. IIRC, and that was for a Lew Horton Smith 24-3 with the Horton holster. Same with scopes, most I ever paid was $150 for a period correct Lyman Jr Targetspot for my 52 Winchester- which I paid $5.00 for. Yes, $5.00.

So yeah, $90.00 is a significant amount to some of us.

Last edited: