wquiles

Well-Known Member

Although I really like my custom .358Win mauser, I have always hated the bolt - specifically the bolt head. A couple of weeks ago, when myself and others got to shoot it with subsonic loads (my cast Lee 200gr PC load), everyone included myself had a hard time operating the bolt - not only that, but being it was so close to the scope and mounts, about 1/3 of the folks got cut/scraped while operating the bolt. Now that I am vacation, and had time to think, I decided to "fix" that bolt for good.

Before pictures:

I browsed the internet on and off for several days looking at pictures to get ideas/inspiration, and then decided to call my mentor and long time friend for advice. He recommended oxy/acetylene to bend it and possibly remove the "ball". I settled on bending like he suggested, and then making a threaded stem to then manufacture a suitable bolt head.

I followed my mentors advice to setup the right tip on the gas welding torch, and had plenty of soaked rags to prevent over-heating the bolt body itself:

Once at temperature, and by trial and error (3x tries on the rifle), I was able to get it bend "just right":

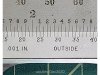

I then took a bolt as a guide, and I ground down the ball until it was "close enough" to start threading by hand (using a tap):

Before pictures:

I browsed the internet on and off for several days looking at pictures to get ideas/inspiration, and then decided to call my mentor and long time friend for advice. He recommended oxy/acetylene to bend it and possibly remove the "ball". I settled on bending like he suggested, and then making a threaded stem to then manufacture a suitable bolt head.

I followed my mentors advice to setup the right tip on the gas welding torch, and had plenty of soaked rags to prevent over-heating the bolt body itself:

Once at temperature, and by trial and error (3x tries on the rifle), I was able to get it bend "just right":

I then took a bolt as a guide, and I ground down the ball until it was "close enough" to start threading by hand (using a tap):

Last edited: