Canuck Bob

Active Member

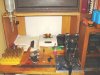

A Stack-On reloader bench, the simple cheap version, went on serious clearance at a local tool store. I bought one and get it later this week. I'm finally setting up my reloading room, shared storage room, and starting reloading again. Lead work will be relegated to the parking pad or garage workshop later in the winter. Sadly, I'm a good woodworker but my health has stalled the project. Time to plow ahead and get setup.

Any tidbits of reloading shop wisdom sure welcome. For now it will be a Lyman T Mag press and hand tools.

Any tidbits of reloading shop wisdom sure welcome. For now it will be a Lyman T Mag press and hand tools.