Ian

Notorious member

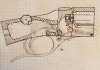

I worked out a simpler sketch on my lunch break, the hammer spring and strut attach to the cocking lever vertically just behind the bolt and pin to the lever. The strut passes through a hole in the hammer and has a tee-head or nut on top. The lever cocks the fired hammer and the strut passes back through the cocked hammer when closing the lever. One piece hammer, integral strut/cocking rod, and spring. Minimal parts, plenty of room for it all, very simple.

The challenge I'm working on right now is the firing pin mechanism. Still toying with the vertical transfer pin, thinking a long taper at the top and a radiused firing pin installed with a threaded breech face bushing and spring. Breech not bored through for either pin. Hammer drives a floating transfer pin upward in a drilled hole, it hits the firing pin and the wedge angle drives it forward into the primer cup. The advantages are safety (firing pin can't blow out the back of the bolt), the firing pin will be wedged into the primer mechanically, preventing primer cup blowout from rejecting the pin, there are no pivot pins to get beaten up from repeated shock loads in shear, and it requires a minimum of metal to be removed from the bolt. The DISadvantage is the lack of mechanical advantage and high frictional losses of transferring firing pin force 90 degrees by one angle-tipped pin driving into another. I'll try to work up some drawings.

I definitely want an over-centering toggle link between lever and bolt. Reasons are many. A plunger and spring in the lever can act against a notch in the bottom of the link to keep the lever closed, the bolt can't be pushed open unless the lever is pulled, and the lever can have a lobe on it that directly contacts the bottom of the bolt slot right at the end of closed travel to lock it upward and double with the link to hold the bolt locked. Also it is a sacrificial part of sorts, a piece that can be easily remade or adjusted over the lifetime of the rifle. Since the link is mounted on pins, there is no sliding part and hence very little friction compared to a pin in a slot.

The challenge I'm working on right now is the firing pin mechanism. Still toying with the vertical transfer pin, thinking a long taper at the top and a radiused firing pin installed with a threaded breech face bushing and spring. Breech not bored through for either pin. Hammer drives a floating transfer pin upward in a drilled hole, it hits the firing pin and the wedge angle drives it forward into the primer cup. The advantages are safety (firing pin can't blow out the back of the bolt), the firing pin will be wedged into the primer mechanically, preventing primer cup blowout from rejecting the pin, there are no pivot pins to get beaten up from repeated shock loads in shear, and it requires a minimum of metal to be removed from the bolt. The DISadvantage is the lack of mechanical advantage and high frictional losses of transferring firing pin force 90 degrees by one angle-tipped pin driving into another. I'll try to work up some drawings.

I definitely want an over-centering toggle link between lever and bolt. Reasons are many. A plunger and spring in the lever can act against a notch in the bottom of the link to keep the lever closed, the bolt can't be pushed open unless the lever is pulled, and the lever can have a lobe on it that directly contacts the bottom of the bolt slot right at the end of closed travel to lock it upward and double with the link to hold the bolt locked. Also it is a sacrificial part of sorts, a piece that can be easily remade or adjusted over the lifetime of the rifle. Since the link is mounted on pins, there is no sliding part and hence very little friction compared to a pin in a slot.