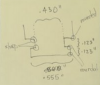

Exactly. I looked at what Rick had and was concerned about pinching my fingers between ram and die. I simply reversed it so the check sits on the flare tool and fingers can stay well clear.Al used Brad's check sizer as his prototype. Brad used my check sizer for his inspiration and actually made a big improvement in it by simply reversing the set up. The idea is simply that checks that fit properly are flat against the base of the bullet and square to the center line of the bullet and bore.

Mine is OSHA approved!