wquiles

Well-Known Member

One of my best friends got an used, but high-end bike carrier designed to go into a standard 2" hitch. It comes with a long adjustment screw that eliminates "play" once in place, making it nice and quiet.

He has the older version, with a plastic knob who's diameter is too large, and rubs when stored on the ground:

The newer version is a smaller diam knob that does not have this problem:

After lots of use, his knob broke. He was sent a new one, but with the same design, so only a mater of time before it breaks again. He asked me I could make him a new knob that would not break again. I did

Before pictures:

I first tried to cut the plastic off with my dremel, but it was glue/pressed in place, so I decided to turn it down on the lathe instead:

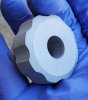

Then I found a suitable piece of Al to make the new knob:

After I got the OD, then spot drill, drill to size:

Test fit:

He has the older version, with a plastic knob who's diameter is too large, and rubs when stored on the ground:

The newer version is a smaller diam knob that does not have this problem:

After lots of use, his knob broke. He was sent a new one, but with the same design, so only a mater of time before it breaks again. He asked me I could make him a new knob that would not break again. I did

Before pictures:

I first tried to cut the plastic off with my dremel, but it was glue/pressed in place, so I decided to turn it down on the lathe instead:

Then I found a suitable piece of Al to make the new knob:

After I got the OD, then spot drill, drill to size:

Test fit: