USSR

Finger Lakes Region of NY

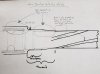

Having 2 brass molds for my 45-70, one of which was made by Accurate Molds, I decided I needed something that would cast about a 300 grain bullet. You see, my Uberti made Winchester 1886 only weighs 7.1 pounds, and from the bench the 345 grain and 405 grain bullets pound me pretty good. Besides, who doesn’t enjoy getting a new brass mold. Since I knew what to expect from Tom at Accurate Molds (top quality/easy casting), I went to his website looking for a .46 caliber bullet in the 300 grain range. Unfortunately, there was nothing there that appealed to me. I starting looking at his .45 caliber molds. His 45-290H mold was exactly what I had in mind. So, I contacted Tom about the possibility of bumping the diameter up on this bullet to .460”. No problem he said, however, since it was to be used in a 45-70 rifle, he suggested a slightly smaller diameter on the front band by pointing out that SAAMI spec’s for the 45-70 has a short throat and needs the smaller diameter. So, that was what the mold specifications were: .460” diameter instead of .452”, and the smaller diameter front band. Had my first casting session today, and am very pleased with the result. Here’s a drawing of the original 45-290H mold.

Don