Had this mould for too long not to be at least,trying it. Early stages of weighing and mikeing.... but,they're running a touch bigger in both,the nose and body than my Lee mould.

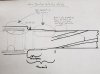

Ran the body of this one down through a inhouse built .287 sizing die..... nose,as cast.

Fresh,factory cases.... pulled JB's,ran the cases up into an M die so that the sized bullet's GC allllllmost is completely down in the expanded case.

Then,without seating any deeper...RAMMED it up into an R700 factory chamber. Which seated and stuck it pretty hard. Knocked it out so ignore tip damage. As measured,the nose section is a touch fat. But you can clearly see the rifling engrave.... and further,can see on the bullet how far it got shoved in the case....

Which gives me at least,a starting point on OAL.

I like the mould's quality,more or less. The RCBS moulds that I have are a little trouble,and that isn't quite the word but...... the sprue plate hold down bolt "could" be better. And the plates,hangover thingy,the part that gets tapped to open is a little short. My RCBS handle's bolt absolutely sucks....needing constant attention.

But will say this.....

Halfarsed cleaned the virgin mould. Ran 3 heat cycles on the kitchen stove,then preheated and started casting. Within a dz casts,it was wanting to "come around"(breaking in)....... interestingly am trying to break in a Lee 309-150F and it's coughing/puking/bucking bad. It's just one of those things that makes it all interesting?

The 7mm alloy is clean range scrap with a bit of Rotometal,dang near lino thrown in. The RCBS,like it..... this particular Lee,not so much.

Ran the body of this one down through a inhouse built .287 sizing die..... nose,as cast.

Fresh,factory cases.... pulled JB's,ran the cases up into an M die so that the sized bullet's GC allllllmost is completely down in the expanded case.

Then,without seating any deeper...RAMMED it up into an R700 factory chamber. Which seated and stuck it pretty hard. Knocked it out so ignore tip damage. As measured,the nose section is a touch fat. But you can clearly see the rifling engrave.... and further,can see on the bullet how far it got shoved in the case....

Which gives me at least,a starting point on OAL.

I like the mould's quality,more or less. The RCBS moulds that I have are a little trouble,and that isn't quite the word but...... the sprue plate hold down bolt "could" be better. And the plates,hangover thingy,the part that gets tapped to open is a little short. My RCBS handle's bolt absolutely sucks....needing constant attention.

But will say this.....

Halfarsed cleaned the virgin mould. Ran 3 heat cycles on the kitchen stove,then preheated and started casting. Within a dz casts,it was wanting to "come around"(breaking in)....... interestingly am trying to break in a Lee 309-150F and it's coughing/puking/bucking bad. It's just one of those things that makes it all interesting?

The 7mm alloy is clean range scrap with a bit of Rotometal,dang near lino thrown in. The RCBS,like it..... this particular Lee,not so much.

Last edited: