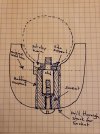

OK, ten days into the project and one trip to the range. Pillar bedding the main screw at the middle of the action worked just fine for control of the vertical. The depth in the stock was set with a small area at the very rear of the action, just behind the safety. Once this was established I bedded a washer in the stock under the recoil lug so that the lug bottom and the rear third of the lug are tight, but I can disassemble the rifle. Now there are three points of bedding; rear of action, main bolt and recoil lug. The forend was sanded to free float the barrel.

The first trip to the range was interesting. While the wide swings were gone, also the first four-shot groups size doubled. So while I was there, I put some business cards between the barrel and the tip of the forend, maybe 3 or 4 pounds of up pressure. Group size went down to the original cold barrel size of about 3/4". Only got the one group fired before a case head separated (old brass I should have thrown away 3 loadings ago) and was done for the day.

Next up will be to use the new bedding to position a little forend support.