RBHarter

West Central AR

275 Rigby / 7×57 Mauser

The Rifle was an 06' and extremely touchy about case capacity, Donna , short for Prima Donna...... 1965 Savage 110LH marked 275 Rigby on prefit Adams and Bennett 24" barrel . Currently unfired , cleaned, amateur lapped at to pick off major burrs and find tight/loose places .

New 1971 Winchester 7mm Mauser cases unfired and untouched by human hands .

3@20 total of 60 one lot .

Weigh lotted ,169.0-170.6 gr electronic scale resolves to .2 gr . Length @ 2.230 +- .002 w/Starett 2.0-3.0 micrometer .

169.0 @3

169.2 @16

169.4 @8

169.6 @8

169.8 @7

170.0 @5

170.2 @7

170.4 @7

170.6 @1

I've decided to use the largest .5 gr lot of brass and blame fliers on case variations. So cases will be 169.2 through 169.8 lots and add the 169.0 to make out 40 cases.

Cast bullets used RCBS 7mm-168 @ 178.6-179.0 gr bare , and NOE 287-150 Hunter @ 151.2-151.4 gr naked . Both gained about 2.2 gr with checks and lube applied . Sized .285 . The alloy ......well roof jacks a probably WW . I don't know really it's about a 16 bhn 2 weeks old and water dropped from the mould .

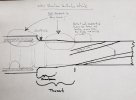

Bore groove dia .278×.284 . The 7-168 touches full contact about .15 on the nose the 287-150 is set off the lands about .1 as it needs to cover the lube groove .

I'm out of practice I guess .......

The 287-150 was loaded with 6.0 Unique, I didn't get a chronograph reading them . 8 rounds in FC 59 Match formed brass . I chose these to ensure the scope and barrel were pointed in the same general area. As luck would have it it was on the vertically . About 8" high . It strung a little but since it was an unfired barrel , fresh install , rearranged optics etc . They landed in about 3" strung vertically and left . Fired at 25 yd .

Next up was the virgin Win brass loaded with the 7mm-168 SP . The first 10 were loaded with 9.0 Unique and the first 5 hit kind of wild just above the first load but fired at 50 yd . An adjustment was made and the over was lowered to only about 4" high and left . But they pulled into more like 1.5" .

The next load was was 10.5 Unique . About 2" I take responsibility for at least a 1/2" of that . These loads had a dark smudge in the leade suggesting a little more size might be in order . Heating mat have been working against me too .

Last up 38 gr of IMR 4831 . Dad had several lbs so I may as well put them to work . 2040 fps . The Strelok app says at 2000 fps MV the 50 yd velocity is 1874 fps and 1145 ftlb holding 971 ftlb at 100 yards . That's within my target goal for the load .

The first 4 presented about a 2" triangle 4" high and right .

The 5th I put in to a wasted 48qt cube cooler full of water . The hope of catching the bullet was wasted . The splash was pretty impressive about a 6 gallon spray the exit in the foam looked to be closer to a dime than .284 .

I'm not disappointed by the bullets or the rifle . Actually if I'm that close to a load the first go then Im pretty happy .

The Rifle was an 06' and extremely touchy about case capacity, Donna , short for Prima Donna...... 1965 Savage 110LH marked 275 Rigby on prefit Adams and Bennett 24" barrel . Currently unfired , cleaned, amateur lapped at to pick off major burrs and find tight/loose places .

New 1971 Winchester 7mm Mauser cases unfired and untouched by human hands .

3@20 total of 60 one lot .

Weigh lotted ,169.0-170.6 gr electronic scale resolves to .2 gr . Length @ 2.230 +- .002 w/Starett 2.0-3.0 micrometer .

169.0 @3

169.2 @16

169.4 @8

169.6 @8

169.8 @7

170.0 @5

170.2 @7

170.4 @7

170.6 @1

I've decided to use the largest .5 gr lot of brass and blame fliers on case variations. So cases will be 169.2 through 169.8 lots and add the 169.0 to make out 40 cases.

Cast bullets used RCBS 7mm-168 @ 178.6-179.0 gr bare , and NOE 287-150 Hunter @ 151.2-151.4 gr naked . Both gained about 2.2 gr with checks and lube applied . Sized .285 . The alloy ......well roof jacks a probably WW . I don't know really it's about a 16 bhn 2 weeks old and water dropped from the mould .

Bore groove dia .278×.284 . The 7-168 touches full contact about .15 on the nose the 287-150 is set off the lands about .1 as it needs to cover the lube groove .

I'm out of practice I guess .......

The 287-150 was loaded with 6.0 Unique, I didn't get a chronograph reading them . 8 rounds in FC 59 Match formed brass . I chose these to ensure the scope and barrel were pointed in the same general area. As luck would have it it was on the vertically . About 8" high . It strung a little but since it was an unfired barrel , fresh install , rearranged optics etc . They landed in about 3" strung vertically and left . Fired at 25 yd .

Next up was the virgin Win brass loaded with the 7mm-168 SP . The first 10 were loaded with 9.0 Unique and the first 5 hit kind of wild just above the first load but fired at 50 yd . An adjustment was made and the over was lowered to only about 4" high and left . But they pulled into more like 1.5" .

The next load was was 10.5 Unique . About 2" I take responsibility for at least a 1/2" of that . These loads had a dark smudge in the leade suggesting a little more size might be in order . Heating mat have been working against me too .

Last up 38 gr of IMR 4831 . Dad had several lbs so I may as well put them to work . 2040 fps . The Strelok app says at 2000 fps MV the 50 yd velocity is 1874 fps and 1145 ftlb holding 971 ftlb at 100 yards . That's within my target goal for the load .

The first 4 presented about a 2" triangle 4" high and right .

The 5th I put in to a wasted 48qt cube cooler full of water . The hope of catching the bullet was wasted . The splash was pretty impressive about a 6 gallon spray the exit in the foam looked to be closer to a dime than .284 .

I'm not disappointed by the bullets or the rifle . Actually if I'm that close to a load the first go then Im pretty happy .