Snakeoil

Well-Known Member

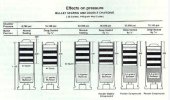

As I was getting ready to test some breech seating loads in my .38-55 on Wed., I ran some numbers in GRT to confirm expected MV from the loads so I'd know if I had enought scope adjustment to get me out to 500 yds. What was very striking was what small differences in case volume would have on MV. I realize that case volume is a variable that has to be considered in developing a load. But I guess I never looked hard at the numbers until I started playing with GRT.

At Wilton, I was talking to another member who is a die-hard single shot shooter. He is the impetus behind the NRA .22 BPCR matches held twice a month on Saturdays at the club. We were talking about breech seating and he asked if I was planning on having a powder measure on the bench and using just one case. I said no. He said Dave Hicks said there is really something to using just one case. For those who do not know Dave, he was on the US BPCR team and set and I believe still holds a few records out to 1500 yds with his High Wall in .45-70 that is throated to be more like a .45-120. I can see Dave's point. The breech seater is fixed in how far it places the bullet in the bore. With one case, the case volume never changes. So, bullet density, powder charge accuracy (smokeless) and primer consistency are you only 3 mechanical variables. Weigh your bullets, use match primers and use a powder that meters like 2400 and given you find a load that the rifle likes, you have the potential to shoot some bad-ass groups, at extended distances, range conditions notwithstanding.

Just might try this one case technique as a winter therapy project. Of course that means I'll need to bring a powder measure to the range, long with my scale. I keep trying to make shooting easier. But if this keeps up, I'm gonna need a wheelbarrow to bring all my crapola to the range.

At Wilton, I was talking to another member who is a die-hard single shot shooter. He is the impetus behind the NRA .22 BPCR matches held twice a month on Saturdays at the club. We were talking about breech seating and he asked if I was planning on having a powder measure on the bench and using just one case. I said no. He said Dave Hicks said there is really something to using just one case. For those who do not know Dave, he was on the US BPCR team and set and I believe still holds a few records out to 1500 yds with his High Wall in .45-70 that is throated to be more like a .45-120. I can see Dave's point. The breech seater is fixed in how far it places the bullet in the bore. With one case, the case volume never changes. So, bullet density, powder charge accuracy (smokeless) and primer consistency are you only 3 mechanical variables. Weigh your bullets, use match primers and use a powder that meters like 2400 and given you find a load that the rifle likes, you have the potential to shoot some bad-ass groups, at extended distances, range conditions notwithstanding.

Just might try this one case technique as a winter therapy project. Of course that means I'll need to bring a powder measure to the range, long with my scale. I keep trying to make shooting easier. But if this keeps up, I'm gonna need a wheelbarrow to bring all my crapola to the range.