JonB

Halcyon member

I agree with Spindrift, that Lee's "process is quite operator-dependant."I use the Lee hardness tester occationally. It seems to work for me. But since the process is quite operator-dependant, I take the results with a grain of salt.

But I believe I can use it to get an impression whether my new batch of alloy is about as hard as the last one.

For terminal ballistic evaluation, I prefer to shoot i an expansion medium, like water.

.

To get familiar with the Lee, I'd suggest getting some known alloys of Pure, and Lino, and 90-5-5, cast up a bunch and take a bunch of readings. To get consistent results with the Lee, you really need to be precise with every part of your measuring process and don't vary that once you have it dialed in. I measure several bullets for a sampling, because you can get a outlier reading here and there.

.

I use the Lee exclusively and I use it fairly often, due to the alloys I use. I will schmelt a bunch of scrap alloys together and I usually have a idea of what they should be, I like to confirm that during the first couple of bullet casting sessions.

.

I permanently mounted the Lee measuring tube in cheapo, child's plastic scientific adjustable microscope, works great, needs lots of light, I use a flashlight when the room isn't bright enough. With that setup, I can easily judge to half a graduation.

.

Pro-tip:

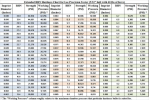

Keep a copy of the "extended" hardness chart.

But, I tend to ignore Lee's PSI numbers, YMMV.

Last edited: