Snakeoil

Well-Known Member

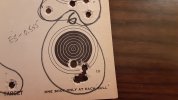

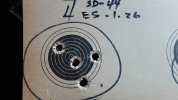

Well, it's done. But, I'm not sure if I'm happy with it. What I learned is something that had been mentioned in the breech seating thread by GWarden, which is the bullets are normally of a softer alloy, like 25:1. The bullets I had cast were 20:1 and the commercial bullets I have are 15 Bn. The importance of the softer alloy is the reduced effort required to push the bullet up into the bore. I'm sure you have seen those breech seating tools that are simply a bent rod with a case solder on the end and a ram to push the bullet into the bore. You'd never be able to use one of those with thee hard bullets.

With the bullets I have, the tool works, but not sure it will hold up from repeated use/abuse. Everything is aluminum other than the plunger so wear and distortion are a higher risk. But, I knew that going in. I made it from aluminum because steel would have been a lot more work and can mark the rifle if not careful. Brass would be the right material, but it too pricey to make into chips and not come out with a useable product. Part of the problem is that damn ejector direction guide at the back of the action. The right thing to do is take the rifle apart and simply remove it. With that gone, the shank of the tool could have been more robust. Miroku was not considering breech seating when they designed that part.

My plan was to put a nice walnut handle on the tool made from a tree that was cut down a couple years ago at Charlie's shop. I've not done that yet as I'm waiting to see how the tool works and holds up after repeated use.

I might remake one of the parts you see below. The mounting bracket for the toggle link is only 3/8" thick. The force it sees is more than I expected (hard bullets). I'm thinking of making a new one from 3/4" stock which will give it more lateral strength.

Here are photos of the finished tool. First the piece parts and then the assembly.

With the bullets I have, the tool works, but not sure it will hold up from repeated use/abuse. Everything is aluminum other than the plunger so wear and distortion are a higher risk. But, I knew that going in. I made it from aluminum because steel would have been a lot more work and can mark the rifle if not careful. Brass would be the right material, but it too pricey to make into chips and not come out with a useable product. Part of the problem is that damn ejector direction guide at the back of the action. The right thing to do is take the rifle apart and simply remove it. With that gone, the shank of the tool could have been more robust. Miroku was not considering breech seating when they designed that part.

My plan was to put a nice walnut handle on the tool made from a tree that was cut down a couple years ago at Charlie's shop. I've not done that yet as I'm waiting to see how the tool works and holds up after repeated use.

I might remake one of the parts you see below. The mounting bracket for the toggle link is only 3/8" thick. The force it sees is more than I expected (hard bullets). I'm thinking of making a new one from 3/4" stock which will give it more lateral strength.

Here are photos of the finished tool. First the piece parts and then the assembly.