Snakeoil

Well-Known Member

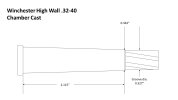

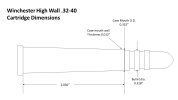

Today was first day at the range with the High Wall. This is pretty much an all original gun. Coil spring action made in 1917. No records available at Cody for 1885's made after SN 115XXX due to fire at Winchester. Bore is oversize for a .32-40. Should be .320-.321 groove diameter and mine slugs at 0.326 groove diameter. I have 500 Saeco 632 (165 gr) bullets which is the standard in the rifle. But they are sized .321. So, I did not have any high expectations for them. And being commercially made bullets, they are hard as a rock so the chances of them bumping up to fill the bore was about zero. But I had a friend say that they'd shoot lull me into believing they would. I loaded 30 rounds with high hopes (aka pipe dreams) of them shooting somewhat decent.

Target was set at 100 yds. No sight settings. Rear is a Lyman tang sight with windage. But the aperture hole is big enough to drive a truck thru. I ended up with a fine crosshair in the Lyman 17 front (Lee Shaver insert). But I really wanted a scope. The target was a 50 foot indoor pistol target so the bullseye was tiny at 100 yds. The crosshair, as fine as it was, obliterated the bullseye. I did not have an front aperture insert that was small enough. Not sure that they make one.

So, my buddy Steve is on the spotting scope and it took a few rounds to get on the berm. I bore sighted it (using the bore and the sight) to start and whacked the 50 yd berm once, then hit the 100 yd berm, adjusted and hit the 50 yd berm again. The rounds were not hard to spot in the dirt, but were all over the place. I finally got one on the backer board for the target and it made it obvious why I was struggling to get on target. Needless to say, that bullet probably exited the barrel with close to zero spin and just tumbled down the range until it found the target... or the berm

Steve says, "I think it keyholed." My guess is he did not believe his eyes. I fired a couple more rounds and they continued to scatter up, down, right and left Backer is about 3 feet square and I'm still smacking dirt after that keyhole. The next round hits the backer and Steve says "Looks like a keyhole.". That's it. No more mini-bullets.

Steve had 11 rounds left over from last Sunday so he brought them. His were sized 0.323. Some printed normal and one keyholed. So, I gave up on Steve's rounds.

I then moved to my other buddy Paul's bullets. I had come up with a liquid lube that I mentioned in the Lube forum as part of No More Johnsons Paste Wax thread. Bascially, Paul Matthews BP lube that I used with great success in years past, made into a viscous liquid using acetone. I coated Paul's bullets which measure about 0.325 as-cast and breech seated them. I had planned for this and had 20 cases charged with 12.3 of 2400. These did much better. There were two bullets. One was an NOE 175 gr similar to the Saeco 315. The other was some long nose Lee bullet that Paul tells me that I cut the GC out of the mold. I believe him, but have no memory of doing it. It too measures about .325 out of the mold. Both of those bullets, shot much better. Here is the target.

Now keep in mind that there were some sight adjustments. But I had flyers as well so which one not in the black that was a flyer and which was a sighter is of little importance. Note the 3 at 3:00 in the black. They were shot in sequence and then the next one was at 5:00 in the 4 ring. I really cannot say if it was a flyer or me since I was struggling to get a clearn sight picture. I really needed a Hadley or Merit eye cup. I have them. Just forgot to screw one into the sight.

Steve had me crank about 5 minutes of windage and elevation into the sight to start another group. The two touching at 10:00 in the 6 ring were part of that group, along with the flyers above it. But again, the bullets were still 0.001 under groove diameter and my experience the bullet has to be at least 0.001 over groove diameter to shoot well.

So, the rifle has promise. I think I'm going to bite the bullet and have Accurate make a custom mold for me that will drop a 0.328 bullet.

I did run a patch down the bore during the shooting session and there was zero lead. The patch was simply black and greasy, obviously from the lube. But, the lube could be playing a role in the accuracy.

Another thing I looked at when I got home was the muzzle. I was expecting a nice start shaped pattern on the muzzle. There was hardly anything and what was there was not uniform. So, a new crowning might be required.

Target was set at 100 yds. No sight settings. Rear is a Lyman tang sight with windage. But the aperture hole is big enough to drive a truck thru. I ended up with a fine crosshair in the Lyman 17 front (Lee Shaver insert). But I really wanted a scope. The target was a 50 foot indoor pistol target so the bullseye was tiny at 100 yds. The crosshair, as fine as it was, obliterated the bullseye. I did not have an front aperture insert that was small enough. Not sure that they make one.

So, my buddy Steve is on the spotting scope and it took a few rounds to get on the berm. I bore sighted it (using the bore and the sight) to start and whacked the 50 yd berm once, then hit the 100 yd berm, adjusted and hit the 50 yd berm again. The rounds were not hard to spot in the dirt, but were all over the place. I finally got one on the backer board for the target and it made it obvious why I was struggling to get on target. Needless to say, that bullet probably exited the barrel with close to zero spin and just tumbled down the range until it found the target... or the berm

Steve says, "I think it keyholed." My guess is he did not believe his eyes. I fired a couple more rounds and they continued to scatter up, down, right and left Backer is about 3 feet square and I'm still smacking dirt after that keyhole. The next round hits the backer and Steve says "Looks like a keyhole.". That's it. No more mini-bullets.

Steve had 11 rounds left over from last Sunday so he brought them. His were sized 0.323. Some printed normal and one keyholed. So, I gave up on Steve's rounds.

I then moved to my other buddy Paul's bullets. I had come up with a liquid lube that I mentioned in the Lube forum as part of No More Johnsons Paste Wax thread. Bascially, Paul Matthews BP lube that I used with great success in years past, made into a viscous liquid using acetone. I coated Paul's bullets which measure about 0.325 as-cast and breech seated them. I had planned for this and had 20 cases charged with 12.3 of 2400. These did much better. There were two bullets. One was an NOE 175 gr similar to the Saeco 315. The other was some long nose Lee bullet that Paul tells me that I cut the GC out of the mold. I believe him, but have no memory of doing it. It too measures about .325 out of the mold. Both of those bullets, shot much better. Here is the target.

Now keep in mind that there were some sight adjustments. But I had flyers as well so which one not in the black that was a flyer and which was a sighter is of little importance. Note the 3 at 3:00 in the black. They were shot in sequence and then the next one was at 5:00 in the 4 ring. I really cannot say if it was a flyer or me since I was struggling to get a clearn sight picture. I really needed a Hadley or Merit eye cup. I have them. Just forgot to screw one into the sight.

Steve had me crank about 5 minutes of windage and elevation into the sight to start another group. The two touching at 10:00 in the 6 ring were part of that group, along with the flyers above it. But again, the bullets were still 0.001 under groove diameter and my experience the bullet has to be at least 0.001 over groove diameter to shoot well.

So, the rifle has promise. I think I'm going to bite the bullet and have Accurate make a custom mold for me that will drop a 0.328 bullet.

I did run a patch down the bore during the shooting session and there was zero lead. The patch was simply black and greasy, obviously from the lube. But, the lube could be playing a role in the accuracy.

Another thing I looked at when I got home was the muzzle. I was expecting a nice start shaped pattern on the muzzle. There was hardly anything and what was there was not uniform. So, a new crowning might be required.