You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.32-40 High Wall - A new adventure begins

- Thread starter Snakeoil

- Start date

Snakeoil

Well-Known Member

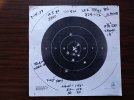

Not a bad group, considering.... But then again, it could have been at 50 ft.I found this on a target butt one day. This poor guy had a bad day.

Snakeoil

Well-Known Member

My buddy with several .32-40 rifles, all that shoot great, pushed one of his bullets down his bore. Said that the rifling barely engraved the bullet. I asked him to bring the bullet to the match on Sunday. He's using 30:1 alloy and that may be the secret. With that soft an alloy, I'm sure they bump up significantly when fired. I might try casting some in 30:1 from borrowed mold that drops .325 bullets to see how they do. Just another excuse to go to the range and shoot.

Bret4207

At the casting bench in the sky. RIP Bret.

Just go over to CPA Rifles and order a Stevens 44. Easy as pie. While you're at it, order one for me too...as long as you're paying!Thats one I also wanted but couldn't locate the proper .321 bbl. I picked up a couple hundred cases and a set of Cowboy dies. My buddy has a John Wayne Commemorative carbine in 32/40 but Id like a single shot I would love ta find a ol Stevens.

CW

Bret4207

At the casting bench in the sky. RIP Bret.

Post it on any of 50 internet boards and you'd find 50 people saying, "Cool!!! That's the buzzsaw effect I've been searching for!!!!!!"...

Snakeoil

Well-Known Member

I cast up about 100 bullets with my friend Paul’s Lee 324-175 mold. GC was machined away so the bullets weigh about 180 gr and measure 0.326. I weighed the 100 I cast and ended up with about 89 that were within 1 grain. I used 30:1 alloy per my buddy Craig’s recommendation.

I sized and lubed 30 of them yesterday using a nose punch for a larger RN bullet. Because the punch did not fit that well, it mooshed the noses just a tiny bit. Really hard to see but I knew they were mooshed. So, today, I made a new nose punch to fit the bullet and sized and lubed another 24 bullets. Plan was to shoot the perfect bullets first and then later, shoot the mooshed ones to see if they shot as well or to the same point of aim, assuming the good ones shot decent. Then I was cutting a piece of foam to put into my ammo box to keep the bullets in the little tray I made and my finger caught the edge of the box, flipped it up enough to launch half the bullets out of their respective locations. DAMN! So, now had a mixed batch of bullets to shoot. I did try to sort them out by looking at the noses. But like I said, you could hardly tell. So, I really had no idea how many got mixed into each group. Oh well…

It was so nice, I decided to head to W’vliet club which is only about 6 or 7 miles from the house to shoot at 100 yds. I loaded 4 test loads. 12.2, 12.3, 12.4, and 12.5 gr of 2400, 10 rounds each. All rounds would be breech seated.

I started with 12.3 because that is where the sights were set from last Wed at Wilton. First shot was off the target. I remembered the last shots at Wilton were all high so I came down about 4 MOA. Hit the bottom of the target. Up 2 MOA and in the 9 ring. Right 2 MOA and in the 10 ring below the bullseye. Close enough. I was using a 50 yd replacement center so much easier to see at 100 yds. I had my smallest aperture in the 17A. My Merit would not fit in this Lyman sight so was stuck with the porthole sized rear aperture in the tang sight.

I had a pretty clear sight picture, even though the setting sun was in my eyes. Ball cap was mandatory equipment. I used up 5 round sighting. I ended up putting last 5 rounds into a group that measured 0.688 and 4 of those were in a group that measured 0.500. Needless to say, I was happy.

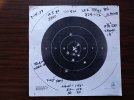

MV averaged 1435 fps with an ES of 64 and SD of 24. Not great numbers, but not bad. And target tells a better story. Here’s the target.

I then moved to 12.2 gr of 2400. Never touched the sights. I had the gun AD while setting the trigger on one round. I had put it on target and then reached in to set the trigger and it went bang when I let go. Put the round into the 8 ring at 9:00. So, that is the round you see below in the target. Otherwise, the target is 3 sets of touching pairs and 1 outlier making a vertical string group of 2.938”. Avg. MV was 1415 fps. ES was 81 and SD was 22. So very similar to the first load shot. Here’s the target. And yes, I adjusted the set trigger.

I ran out of light so I went home. Plan to go back in the morning and shoot the other two test loads.

Things are looking much better for this rifle.

Now, there is another revelation about this rifle. I don’t think that the barrel is original to the action. I say that because the barrel is cut for a flat spring. I know from reading Vol 1 of The Winchester Single Shot Rifle, that all the barrels had the dovetail machined in them right up until the end. So, a coil spring action with a dovetail for a flat mainspring is normal. But, the dovetail in this rifle has been used at some point. The metal is raised on the edges and the blue is scrubbed off on the flat. There is also a circular polished area between the spring dovetail and the forend screw dovetail like another screw had rubbed on the barrel. Yet there is nothing in that area of the forend that could have done that. I suspect that this barrel came off another rifle, and was freshened in the process. I know that flat spring guns were shipped during the period that coil spring guns were made. So, although I have not confirmed the address on the barrel as being from the correct period as the action, if it is correct, that does not mean that the barrel came originally on that action. I need to dig deeper into this. This may have been a take-off barrel from the varmint craze days and was later put onto this action to make it appear original again.

I sized and lubed 30 of them yesterday using a nose punch for a larger RN bullet. Because the punch did not fit that well, it mooshed the noses just a tiny bit. Really hard to see but I knew they were mooshed. So, today, I made a new nose punch to fit the bullet and sized and lubed another 24 bullets. Plan was to shoot the perfect bullets first and then later, shoot the mooshed ones to see if they shot as well or to the same point of aim, assuming the good ones shot decent. Then I was cutting a piece of foam to put into my ammo box to keep the bullets in the little tray I made and my finger caught the edge of the box, flipped it up enough to launch half the bullets out of their respective locations. DAMN! So, now had a mixed batch of bullets to shoot. I did try to sort them out by looking at the noses. But like I said, you could hardly tell. So, I really had no idea how many got mixed into each group. Oh well…

It was so nice, I decided to head to W’vliet club which is only about 6 or 7 miles from the house to shoot at 100 yds. I loaded 4 test loads. 12.2, 12.3, 12.4, and 12.5 gr of 2400, 10 rounds each. All rounds would be breech seated.

I started with 12.3 because that is where the sights were set from last Wed at Wilton. First shot was off the target. I remembered the last shots at Wilton were all high so I came down about 4 MOA. Hit the bottom of the target. Up 2 MOA and in the 9 ring. Right 2 MOA and in the 10 ring below the bullseye. Close enough. I was using a 50 yd replacement center so much easier to see at 100 yds. I had my smallest aperture in the 17A. My Merit would not fit in this Lyman sight so was stuck with the porthole sized rear aperture in the tang sight.

I had a pretty clear sight picture, even though the setting sun was in my eyes. Ball cap was mandatory equipment. I used up 5 round sighting. I ended up putting last 5 rounds into a group that measured 0.688 and 4 of those were in a group that measured 0.500. Needless to say, I was happy.

MV averaged 1435 fps with an ES of 64 and SD of 24. Not great numbers, but not bad. And target tells a better story. Here’s the target.

I then moved to 12.2 gr of 2400. Never touched the sights. I had the gun AD while setting the trigger on one round. I had put it on target and then reached in to set the trigger and it went bang when I let go. Put the round into the 8 ring at 9:00. So, that is the round you see below in the target. Otherwise, the target is 3 sets of touching pairs and 1 outlier making a vertical string group of 2.938”. Avg. MV was 1415 fps. ES was 81 and SD was 22. So very similar to the first load shot. Here’s the target. And yes, I adjusted the set trigger.

I ran out of light so I went home. Plan to go back in the morning and shoot the other two test loads.

Things are looking much better for this rifle.

Now, there is another revelation about this rifle. I don’t think that the barrel is original to the action. I say that because the barrel is cut for a flat spring. I know from reading Vol 1 of The Winchester Single Shot Rifle, that all the barrels had the dovetail machined in them right up until the end. So, a coil spring action with a dovetail for a flat mainspring is normal. But, the dovetail in this rifle has been used at some point. The metal is raised on the edges and the blue is scrubbed off on the flat. There is also a circular polished area between the spring dovetail and the forend screw dovetail like another screw had rubbed on the barrel. Yet there is nothing in that area of the forend that could have done that. I suspect that this barrel came off another rifle, and was freshened in the process. I know that flat spring guns were shipped during the period that coil spring guns were made. So, although I have not confirmed the address on the barrel as being from the correct period as the action, if it is correct, that does not mean that the barrel came originally on that action. I need to dig deeper into this. This may have been a take-off barrel from the varmint craze days and was later put onto this action to make it appear original again.

Petrol & Powder

Well-Known Member

I think there's a lot of promise in that rifle.

Snakeoil

Well-Known Member

Back to the range today. Decided to dump the 12.4 load and make up 13.0 and 13.5 loads. GRT said that would get me into the 1500’s.

So the loads tested were 12.5, 13 and 13.5. There was some wind. But the range has berms on both sides that are lined with trees so not much effect. Sky was blue so no light changes.

My buddy Craig was right. As I went up in powder charge things got better.

12.5 gr load was also the fouling and warm-up shots. So, I circled the first shot which was low. The next 3 moved up and to the right. I considered those 4 fouling and warm-up rounds. I had cleaned the bore with a dry patch last night to see if there was any lead and there was none. All the info is on the target, including the chrono results. I measured the total group minus those 4 first shots and that is the group size. I then measured the best 5 round group.

Here is 13.0 gr of 2400. No shots were considered fouling. 10 rounds and all counted. On this target I used the best four for the smaller group measurement. Still not into the 1500’s yet. But note that the ES and SD are better. Group size reflects the chrono numbers.

Last load of 13.5 gr of 2400 got me into the 1500’s. The total group is tighter and there are 6 rounds within a 7/8” group. The ES and SD numbers are better, too.

Note the vertical stringing still happening, but at a much-reduced rate. I think this is still due to the ES of the loads, but I am also suspect of my rear sight. It has to be locked in place and when you lock it, it rotates it back a bit. What I don’t know is if it stops in that rotation in the same place every time. If not, it will contribute to the vertical stringing. And I have to unlock and fold the sight down every time I load the rifle. When I put a scope on the gun, that will pretty much take the sight variable out of the equation. In the meantime, I think I may make a disc with a smaller aperture for the rear sight and glue it in place as a temporary improvement. I really don’t like this sight, as valuable as it is. I may just put my BPCR long range sight on the rifle. It has a Hadley and a vernier scale with finer graduation for shooting iron sights in matches. Not sure the breech seater can get by it though.

Next move will be more test loads moving up in powder charge. I am going back into GRT today to compare predicted with actual and see if I cannot accurize GRT to better predict the MV for a load in this cartridge. It’s close but could be better.

My Lee mold will arrive tomorrow. Not sure I need it. I might try casting some in 20:1 to see how they shoot. It could be the .38-55 all over again. I know I’ve been stubborn about changing to a softer alloy. But these past 2 days have shown it was the right path. The bigger bullet in 20:1 will either work or not work and confirm or disprove the softer alloy is best. It might be one of those “it depends” kinda things.

So the loads tested were 12.5, 13 and 13.5. There was some wind. But the range has berms on both sides that are lined with trees so not much effect. Sky was blue so no light changes.

My buddy Craig was right. As I went up in powder charge things got better.

12.5 gr load was also the fouling and warm-up shots. So, I circled the first shot which was low. The next 3 moved up and to the right. I considered those 4 fouling and warm-up rounds. I had cleaned the bore with a dry patch last night to see if there was any lead and there was none. All the info is on the target, including the chrono results. I measured the total group minus those 4 first shots and that is the group size. I then measured the best 5 round group.

Here is 13.0 gr of 2400. No shots were considered fouling. 10 rounds and all counted. On this target I used the best four for the smaller group measurement. Still not into the 1500’s yet. But note that the ES and SD are better. Group size reflects the chrono numbers.

Last load of 13.5 gr of 2400 got me into the 1500’s. The total group is tighter and there are 6 rounds within a 7/8” group. The ES and SD numbers are better, too.

Note the vertical stringing still happening, but at a much-reduced rate. I think this is still due to the ES of the loads, but I am also suspect of my rear sight. It has to be locked in place and when you lock it, it rotates it back a bit. What I don’t know is if it stops in that rotation in the same place every time. If not, it will contribute to the vertical stringing. And I have to unlock and fold the sight down every time I load the rifle. When I put a scope on the gun, that will pretty much take the sight variable out of the equation. In the meantime, I think I may make a disc with a smaller aperture for the rear sight and glue it in place as a temporary improvement. I really don’t like this sight, as valuable as it is. I may just put my BPCR long range sight on the rifle. It has a Hadley and a vernier scale with finer graduation for shooting iron sights in matches. Not sure the breech seater can get by it though.

Next move will be more test loads moving up in powder charge. I am going back into GRT today to compare predicted with actual and see if I cannot accurize GRT to better predict the MV for a load in this cartridge. It’s close but could be better.

My Lee mold will arrive tomorrow. Not sure I need it. I might try casting some in 20:1 to see how they shoot. It could be the .38-55 all over again. I know I’ve been stubborn about changing to a softer alloy. But these past 2 days have shown it was the right path. The bigger bullet in 20:1 will either work or not work and confirm or disprove the softer alloy is best. It might be one of those “it depends” kinda things.

CZ93X62

Official forum enigma

I debated whether to have Jesse Ocumpah rebore/rechamber my spoiled Win 94 25/35 to 32/40 vs. 38/55. After much palavering I elected to go 38/55, and don't regret the choice. I still think the 32/40 is a cool cartridge, and to date her grandfather's Win 94 so chambered has not surfaced. Ah, if wishes were fishes we would all limit out.

Petrol & Powder

Well-Known Member

Just a guess from afar, but I agree the sights may be the current limiting factor. The load itself is progressing well and I think you're onto a good formula there.

A smaller aperture may help. Those 6 rounds in 7/8" tend to make me believe the rifle & cartridge are working well together. The sight may be the weak link in that system. Again, just guessing from afar.

A smaller aperture may help. Those 6 rounds in 7/8" tend to make me believe the rifle & cartridge are working well together. The sight may be the weak link in that system. Again, just guessing from afar.

Missionary

Well-Known Member

I would take a caliber .38 Lever over a .30 every time. I can soot 150 grainers in a .38. You cannot shoot 275's in a .30 lever action.

Bret4207

At the casting bench in the sky. RIP Bret.

Snake, I am thinking that as your powder charge increases you are getting better bullet fit. Pressure can be your friend! I wouldn't discount the Lee that's coming yet. It might make things a bunch easier as you won't have to smack it so hard to get the fit you need.

Snakeoil

Well-Known Member

Lee mold arrived today. It was on the doorstep when I got back from Wilton. Never owned one before. First one I ever casted with is the bullet used for the testing above. They are kinda junky. But for the money, do provide a service for those who like to play with molds.

First order of business was machining those damn pins that hold the handles in place. Geesh was a dumb idea. But I realize that no having a threading step for the molds cuts costs and keeps the price low. I used my #29 drill for making the lead lap I used on the bore of the .32-20 and I either set it somewhere or it rolled off the bench and is nowhere to be found. Fortunately I had a beater set of number drills in the garage and although many are missing, there was a 29.

With the pins out, I tapped the holes 8-32 so I could use machine screws to re-attach the handles.

Put the blocks in the 4-jaw chuck and machined the gas check areas to match the diameter of the bottom land. Knocked the stamping burrs off the sprue plate (another step they should do) and the mold is ready to go.

Before doing all this, went to Wilton to shoot the rifle out to 500 yds and hopefully, if it performed, get some sight settings. All went well. Took a bit for the barrel to warm up and get on the chickens at 200. But then it went well. Got on the pigs and she shot consistently to point of aim. There was a nasty wind blowing and although the sun was out, there were puffy clouds that would make the light go up and down and with it my bullets. So, my goal was to get range setting and fine tune the day of the match, which one has to do at every match anyway. When it came time to shoot the turkeys, I cranked up the sight (I was using settings for my Springfield) and hit the turkey on the first shot. I then followed up with another hit with the second shot. It was hard not to grin. Moved to the rams and the light was going up and down and the wind was blowing. But I managed to stay on the target and got a setting.

The fouling star on the muzzle was perfect. Gun shoots well. We have our VT match this weekend, which is round gongs from 100 our to 300 yds. Good match for iron sights. I think I'll cast up some more bullets and shoot the match with this rifle.

The plan for the new Lee bullet is to cast some with my 20:1 alloy and size them to 0.328 and shoot them. They will have to be breech seated. But that's not a problem. If they shoot good, then I'll need to do more testing to see which one shoots the best. This new Lee is a 329-205. So, with the GC removed, probably more like 210gr. That makes it 20 gr lighter than the bullet I shot today and in the testing above.

Looks like I'm going to drill the rifle for a scope. That will make the testing that much more conclusive.

As far as the powder charge goes, I think there is more room for improvement. The chrono numbers are tracking the group sizes. It may be time to start increasing the charge 0.1 gr at a time.

First order of business was machining those damn pins that hold the handles in place. Geesh was a dumb idea. But I realize that no having a threading step for the molds cuts costs and keeps the price low. I used my #29 drill for making the lead lap I used on the bore of the .32-20 and I either set it somewhere or it rolled off the bench and is nowhere to be found. Fortunately I had a beater set of number drills in the garage and although many are missing, there was a 29.

With the pins out, I tapped the holes 8-32 so I could use machine screws to re-attach the handles.

Put the blocks in the 4-jaw chuck and machined the gas check areas to match the diameter of the bottom land. Knocked the stamping burrs off the sprue plate (another step they should do) and the mold is ready to go.

Before doing all this, went to Wilton to shoot the rifle out to 500 yds and hopefully, if it performed, get some sight settings. All went well. Took a bit for the barrel to warm up and get on the chickens at 200. But then it went well. Got on the pigs and she shot consistently to point of aim. There was a nasty wind blowing and although the sun was out, there were puffy clouds that would make the light go up and down and with it my bullets. So, my goal was to get range setting and fine tune the day of the match, which one has to do at every match anyway. When it came time to shoot the turkeys, I cranked up the sight (I was using settings for my Springfield) and hit the turkey on the first shot. I then followed up with another hit with the second shot. It was hard not to grin. Moved to the rams and the light was going up and down and the wind was blowing. But I managed to stay on the target and got a setting.

The fouling star on the muzzle was perfect. Gun shoots well. We have our VT match this weekend, which is round gongs from 100 our to 300 yds. Good match for iron sights. I think I'll cast up some more bullets and shoot the match with this rifle.

The plan for the new Lee bullet is to cast some with my 20:1 alloy and size them to 0.328 and shoot them. They will have to be breech seated. But that's not a problem. If they shoot good, then I'll need to do more testing to see which one shoots the best. This new Lee is a 329-205. So, with the GC removed, probably more like 210gr. That makes it 20 gr lighter than the bullet I shot today and in the testing above.

Looks like I'm going to drill the rifle for a scope. That will make the testing that much more conclusive.

As far as the powder charge goes, I think there is more room for improvement. The chrono numbers are tracking the group sizes. It may be time to start increasing the charge 0.1 gr at a time.

Snakeoil

Well-Known Member

Ran the 329205 Lee bullets thru the sizer after making a nose punch today. Then I thought I'd try to breech seat one of the 20:1 alloy bullets. NO GO! I was able to get it started, but then it stopped and there was no amount of pushin on the breech seater to make it go deeper. I drove it out and then tried one of the 30:1 bullets. Pretty much the same thing. Here are the two bullets. 30:1 is on top.

Note how the nose engraved. I knew it would based upon measurements. When it got to the first land, that was it. Way too much force required to get them any further up the bore. So, looks like this bullet experiment was a failure. But as usual, even with failures, we learn things. Something I took away from this is I suspect that the extra force to seat a bullet that is 0.002 over groove diameter helps increase the chamber pressure and probably makes it more consistent and drives better consistency and hence accuracy for the right bullet/powder/charge combination. But it looks like I won't be going down the 0.002 interference fit path with this rifle.

Anyone need a plain base .329- .330 205 grain bullet mold?? Set screw installed for the sprue plate screw, pins drilled out and 8-32 screws installed. Only used once by a little gray haired old man who cast bullets for his church. (Just joking. Not trying to sell it here).

(Just joking. Not trying to sell it here).

I'll probably find someone at the club that might want it. Otherwise, I'll hang it on the wall of shame.

Note how the nose engraved. I knew it would based upon measurements. When it got to the first land, that was it. Way too much force required to get them any further up the bore. So, looks like this bullet experiment was a failure. But as usual, even with failures, we learn things. Something I took away from this is I suspect that the extra force to seat a bullet that is 0.002 over groove diameter helps increase the chamber pressure and probably makes it more consistent and drives better consistency and hence accuracy for the right bullet/powder/charge combination. But it looks like I won't be going down the 0.002 interference fit path with this rifle.

Anyone need a plain base .329- .330 205 grain bullet mold?? Set screw installed for the sprue plate screw, pins drilled out and 8-32 screws installed. Only used once by a little gray haired old man who cast bullets for his church.

I'll probably find someone at the club that might want it. Otherwise, I'll hang it on the wall of shame.

Petrol & Powder

Well-Known Member

No shame.

Looks like you may be headed for a custom mold. In the grand scheme of things, that's not a bad path.

Your 180 gr bullets at .326" show a lot of promise. That longer and fatter 205ish grain bullet is just a "bridge too far", size wise.

Maybe a custom mold in the 180-200 grain range that drops a bullet at .328" and can be sized down to .327"- .3275"?

You've developed a lot of useful data so far.

Looks like you may be headed for a custom mold. In the grand scheme of things, that's not a bad path.

Your 180 gr bullets at .326" show a lot of promise. That longer and fatter 205ish grain bullet is just a "bridge too far", size wise.

Maybe a custom mold in the 180-200 grain range that drops a bullet at .328" and can be sized down to .327"- .3275"?

You've developed a lot of useful data so far.

Snakeoil

Well-Known Member

Yup, I agree. I have to admit that I've been a hardhead about moving to a softer alloy. I think that might be the problem with the .38-55 as well. It appears the rifle wants a groove diameter bullet in a soft alloy that will bump up and fill the bore completely. My buddy Craig got me to move off 20:1 when he said PB bullets are a different animal. All my PB experience up until now was with BP.

There are several choices of well-proven bullets all copies of or based upon the Saeco 632 165 gr bullet. Accurate will let me define the diameter for each band on the tapered bullet. I have an email into Arsenal asking if I can request a different diameter on their 165 gr bullet that looks very much like the Saeco. Their 200 gr bullet has a note that says you can ask for a different diameter. But the smaller bullet does not have that note. No reply yet so may have to call them.

But this crappy little Lee bullet is shooting well. The testing process just lost the dual path when those bullets would not breech seat. So, now it's just upping the powder charge 1/10 gr at a time and seeing how it does on paper and across the chrono. I am going to shoot this rifle in a match on Sunday that is only out to 300 yds. Will shoot with iron sights.

A good friend who is a gunsmith and has a full machine shop just asked me to do some work on his MVA Winchester replica scope. In return, he's going to drill the rifle for Unertl mounting blocks.

There are several choices of well-proven bullets all copies of or based upon the Saeco 632 165 gr bullet. Accurate will let me define the diameter for each band on the tapered bullet. I have an email into Arsenal asking if I can request a different diameter on their 165 gr bullet that looks very much like the Saeco. Their 200 gr bullet has a note that says you can ask for a different diameter. But the smaller bullet does not have that note. No reply yet so may have to call them.

But this crappy little Lee bullet is shooting well. The testing process just lost the dual path when those bullets would not breech seat. So, now it's just upping the powder charge 1/10 gr at a time and seeing how it does on paper and across the chrono. I am going to shoot this rifle in a match on Sunday that is only out to 300 yds. Will shoot with iron sights.

A good friend who is a gunsmith and has a full machine shop just asked me to do some work on his MVA Winchester replica scope. In return, he's going to drill the rifle for Unertl mounting blocks.