Ok Dimner, let's update your posts again.

Dynamic fit is the moving relationship between the contacting surfaces of the bullet and the inside of the barrel. It ceases to matter once the bullet has departed the muzzle.

Try this:

"Broadly, fit is the relationship of measurements between the bullet itself and anything that touches or will touch it inside of the gun, with the emphasis being on tolerance reduction and exact replication. Regardless of the many methods by which the bullet can be fit to the gun, the end goal of any specific mechanical fit technique is starting the bullet absolutely straight into the barrel so that it flies true when it comes out of the muzzle. Bullet fit can be broken down into two categories: Static Fit which is how the bullet shape relates to the firearm at the moment it is about to be fired, and Dynamic Fit which is the moving relationship between the contacting surfaces of the bullet and the inside of the barrel, from chamber to muzzle."

Some questions, so I can make this clear for the simple folk such as myself.

tolerance reduction and exact replication

For this term, do we mean the exact replication (repeatability) of our desired fit each time a round is loaded? I just wanted to be sure I understood. .... oh, I just read your later reply to fiver. I'm going to add a bit of simple man language in there.

...tolerance reduction and exact replication. Exact replication being the repeatability of our desired fit each time a round is loaded.

Static Fit which is how the bullet shape relates to the firearm at the moment it is about to be fired,

Doesn't case prep also impact static fit? Or is it minimal enough that we do not really need to include it in this basic definition?

Or just use what you have on hand and make a robust, dimensionally accurate pound cast.

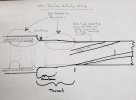

I'm unsure, how to poundcast a semi auto. An AR, I guess I can remove the barrel from the upper. But for a garand, I'm not sure how I would have to leave the barrel on. I'll do some google work on semi auto pound casts. Perhaps, I just pound too hard

Here's another way to make a Marlin with the cathedral throat work and it will blow most people's minds: forget the nose and steer the bullet from the back end, that's what that long neck and small chamber neck clearance is for.

Back end steering and cathedral throat, I'll add those to the list to expand on. Is this the

backseat driver fitting method? ;-)

3⁰ included angle, straight taper nose

I need to start gathering these terms and adding them to the bullet profile section. also, to add a list of bad happenings to look for (flame cut reminded me. Alloy flowing into lube grooves, is this bad or good or situation dependent?

I know for a fact that not all rifles have perfectly concentric (?) starts to the throat/lands interface.

Amen to that. It took alot of cussing and frustration for me to learn that the first time. Simple to assume everything in that chamber and throat is exactly what you see in those chamber drawing diagrams. My very first pound cast, I can say with certainty, included some very frustrated pounding. Once I saw the result, it seemed like the most trivial fact that I had missed.