You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super Hard Bullet Recipe

- Thread starter stlg67

- Start date

Also pretty sure that PCing temps negate most, if not all, "benefits" of water quenching as relates to creating "HARDCAST" type Bhn.

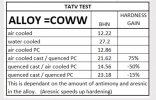

You are very correct, unless you quench out of the oven, water quenching and PC'ing after the fact will put them back softer, for me anyway. I just air cool and try to coat within a few days and let time do the hardening. seems my crazy BHN numbers settled down and the alloy is around 15BHN for me consistently.

As the name implies, this hobby is much more of an Art as it is a Science some days. The art is only developed with time and trial and error. Im still learning too.

JonB

Halcyon member

I'm not a educated metallurgist, but with what I have read and all the "playing" around I've done with scrap Lead alloys, I have to assume if a alloy bullet is filed for measuring hardness with a Lee tester, the work softening only goes as deep as the "lines" left by the file.

ALSO,

I am not convinced that water dropping or heat treating is only hardening the surface...even in those first few weeks, where "things" are still happening with the elements in the alloy...I think it's happening throughout the casting.

Lee's dimple making die has a calibrated Spring loaded tension, so if you follow the instructions as Ian mentioned, you should be applying the correct pressure during each test.

I do agree with all of you who say the Bhn is NOT the end all, Be all, for Speed and/or Pressure. But I believe you need to at least have an idea of what the alloy might be...or what you can add to a mystery alloy, to get it to something that will more likely shoot successfully than not...AND a hardness tester can help with that determination, Other clues shouldn't be excluded in that determination. At least that's what I've found, especially when scrounging alloys from places where the original (or previous) source is unknown.

When I get some totally unknown alloy, I always mix it with whatever range scrap that I have scrounged since my previous smelting session...it kind of "stacks the deck", to get to a good enough alloy...meaning I rarely need to add anything. If the batch measures soft-ish, it goes to 38 or 45acp, if the batch measures hard-ish (like in the COWW zone) it goes for 357m or 41M or Rifle bullets for plinking (1800fps or less).

That's my 2¢

ALSO,

I am not convinced that water dropping or heat treating is only hardening the surface...even in those first few weeks, where "things" are still happening with the elements in the alloy...I think it's happening throughout the casting.

Lee's dimple making die has a calibrated Spring loaded tension, so if you follow the instructions as Ian mentioned, you should be applying the correct pressure during each test.

I do agree with all of you who say the Bhn is NOT the end all, Be all, for Speed and/or Pressure. But I believe you need to at least have an idea of what the alloy might be...or what you can add to a mystery alloy, to get it to something that will more likely shoot successfully than not...AND a hardness tester can help with that determination, Other clues shouldn't be excluded in that determination. At least that's what I've found, especially when scrounging alloys from places where the original (or previous) source is unknown.

When I get some totally unknown alloy, I always mix it with whatever range scrap that I have scrounged since my previous smelting session...it kind of "stacks the deck", to get to a good enough alloy...meaning I rarely need to add anything. If the batch measures soft-ish, it goes to 38 or 45acp, if the batch measures hard-ish (like in the COWW zone) it goes for 357m or 41M or Rifle bullets for plinking (1800fps or less).

That's my 2¢

Bret4207

At the casting bench in the sky. RIP Bret.

I have used the exact same alloy (old WW) from 600fps to over 2300 fps successfully. By success I mean acceptable groups at 25 to 100 yards out of whatever gun we're talking. Might be a 32 Smith + Wesson, a 308, 8mm, 45-70, 35 Whelen, 357, 45 Auto. The fastest stuff has been full-ish load 30-30/303 Savage type stuff, 8x56R (240gr), 8x57(245gr), 35 Whelen (215 gr) and 32-20 (100-115gr). I didn't have any leading, no wild groups, no bug hole groups either, not Ben type groups, but thats partly me. My Cabine Tree tester says my stuff runs about 15-16 Bhn. I don't know what kind of pressures you get pushing an 8X56 to 2300 or a 35 Whelen to near 2500, but they felt pretty stout on the butt end. I've tried water quenching and saw no difference in accuracy in any of the guns I shot it in. Maybe I'm just lucky to have gotten those results. But I've had dogs too. My '03 will not shoot cast at all. But that because the barrel is knee deep in 100 years of jacket fouling. My Win 94 hates the Lee Soup Can. My Smith Perfected Model 38S+W wants a fatter bullet than I can make. My Ruger BH with the 45ACP cylinder shoots everything great. My Smith '17 with the shallow rifling wants fatter bullets than the Ruger. My Marlin 336SC 35 Rem has the pre-MG rifling and likes this Lee 35-180FPGC I got someplace, but it isn't crazy about the 358156 if you push it too fast.

My point- you gotta shoot and see. We all want there to be an easy answer we can measure and fix. Bhn isn't that answer, at least it's not in the top 3 or 5 or even 10 things for most people. Static fit first, dynamic fit 2nd. Then follows powder charge, diameter, seating depth, neck tension, crimp/no crimp and 50 other things. Bhn is in there someplace, but I think it's going to jump from # 11 to #4 to #19 depending on exactly what else you're doing. And that's with each bullet! Change the bullet and you start all over again.

I'm not saying this is THE ANSWER or the only way. I'm just saying that freakin' "HARDCAST" CRAP has led more people on a wild goose chase than anything else I can think of in this game. Why am I so pig headed and crabby about it? Because I wasted YEARS chasing that rabbit before Felix Robbins spoke and mentioned "static fit and dynamic fit" and then the light came on! FIT, FIT, FIT!!!!! Everything is relative to FIT! That includes Bhn. The "experty experts" say you can't shoot softer lead alloys over about 1100 fps. I guarantee you there are guys here shooting stuff in the 8-9 Bhn range way over that.

Alright, I'm done. I hoe no one getting into this thinks I'm saying you have to do anything my way. I'm just trying to save them some time and frustration.

My point- you gotta shoot and see. We all want there to be an easy answer we can measure and fix. Bhn isn't that answer, at least it's not in the top 3 or 5 or even 10 things for most people. Static fit first, dynamic fit 2nd. Then follows powder charge, diameter, seating depth, neck tension, crimp/no crimp and 50 other things. Bhn is in there someplace, but I think it's going to jump from # 11 to #4 to #19 depending on exactly what else you're doing. And that's with each bullet! Change the bullet and you start all over again.

I'm not saying this is THE ANSWER or the only way. I'm just saying that freakin' "HARDCAST" CRAP has led more people on a wild goose chase than anything else I can think of in this game. Why am I so pig headed and crabby about it? Because I wasted YEARS chasing that rabbit before Felix Robbins spoke and mentioned "static fit and dynamic fit" and then the light came on! FIT, FIT, FIT!!!!! Everything is relative to FIT! That includes Bhn. The "experty experts" say you can't shoot softer lead alloys over about 1100 fps. I guarantee you there are guys here shooting stuff in the 8-9 Bhn range way over that.

Alright, I'm done. I hoe no one getting into this thinks I'm saying you have to do anything my way. I'm just trying to save them some time and frustration.

Last edited:

Ian

Notorious member

I am not convinced that water dropping or heat treating is only hardening the surface...even in those first few weeks, where "things" are still happening with the elements in the alloy...I think it's happening throughout the casting.

It depends on the diameter of the casting and how aggressive is the quench. I said "generally" abive because .30-caliber and smaller bullets tend to quench-harden through and through, though in some instances of .30-caliber, low-antimony bullets I have seen a few points softer right in the center of a bullet slice.

Sorry it just dawned on me what you are saying, I'm making ingots, then I let them air cool. Then I put them in a Lee 20lb pot to make the bullets.Okay. And are you testing ingots or bullets? You will get different readings from them. I understand it's a matter of mass, especially with the impact type testers.

Bret4207

At the casting bench in the sky. RIP Bret.

Okay, then as outlined above, your ingots will give a different reading than a bullet. And the Bhn will change several points over a fairly short period of time, usually gaining a few pts and then eventually losing a few. Honestly guy, sincerely, please don't fret about Bhn. Shoot and see what happens. You may already have everything you need! If you don't, (and you can't tell until you shoot), then work on making the bullet fit the gun, then IF you see no other easy option, then start juicing the alloy you have to alter the Bhn. But that comes AFTER you do the easier, historically more effective things. And even then, HOW you alter the alloy and WHAT you do to cause it to be altered can vary. Bhn is just a one dimensional number. It encompasses multiple parts that combine in different ways to give you a relative number. And then you have to remember that the number you come up with with a Lee tester is a pretty darn rough number. It may be 10 pts off actual Bhn, maybe more, maybe less. If you really want to play this game and worry yourself over Bhn to a big extent, you may want to get a more consistent tester than the Lee. I have a Cabine Tree tester, haven't used it in a good 10 years for Bhn, but it's a great runout tester. LBT makes/made a good one. I don't know who else makes a decent one, but consistency and not having to file off a rounded surface indicate to me that Lee doesn't have the greatest tool out there, and I like Lee, so it's not snobbery.Sorry it just dawned on me what you are saying, I'm making ingots, then I let them air cool. Then I put them in a Lee 20lb pot to make the bullets.

Charles Graff

Moderator Emeritus

Lord have Mercy. I did that about 30 years ago. Three shots and I was done with that. Pulled the rest of the loads.2000fps+45-70=Ouch!.....

Yes sir will try and move forward with your suggestions. ThanksOkay, then as outlined above, your ingots will give a different reading than a bullet. And the Bhn will change several points over a fairly short period of time, usually gaining a few pts and then eventually losing a few. Honestly guy, sincerely, please don't fret about Bhn. Shoot and see what happens. You may already have everything you need! If you don't, (and you can't tell until you shoot), then work on making the bullet fit the gun, then IF you see no other easy option, then start juicing the alloy you have to alter the Bhn. But that comes AFTER you do the easier, historically more effective things. And even then, HOW you alter the alloy and WHAT you do to cause it to be altered can vary. Bhn is just a one dimensional number. It encompasses multiple parts that combine in different ways to give you a relative number. And then you have to remember that the number you come up with with a Lee tester is a pretty darn rough number. It may be 10 pts off actual Bhn, maybe more, maybe less. If you really want to play this game and worry yourself over Bhn to a big extent, you may want to get a more consistent tester than the Lee. I have a Cabine Tree tester, haven't used it in a good 10 years for Bhn, but it's a great runout tester. LBT makes/made a good one. I don't know who else makes a decent one, but consistency and not having to file off a rounded surface indicate to me that Lee doesn't have the greatest tool out there, and I like Lee, so it's not snobbery.

CWLONGSHOT

Well-Known Member

CZ93X62

Official forum enigma

We seem to have a handle on bullet "hardness" with all of the above discussion. before I expand into the core content of my post (the things we do that can screw up our carefully-cast and carefully-prepared bullets), I have to add in here that some good side-effects might result from the too-hard-for-application alloys that have been cheered from the cheap seats since the beginning of time.

One possible benefit that uber-hard alloys might offer is their ability to withstand down-sizing in the under-expanded case necks/mouths of our brass when it is processed in modern die sets--which are largely biased toward the loading of the Red-Coated Pretenders. This assumes that your bullets of whatever hardness were well-fit to the throat(s) of the firearm(s) you are launching them through in the first place. FIT IS KING. Metallurgy & lube/coating won't matter a damn if the bullets don't fit when The Big Light hits them.

And those bullets won't fit if they get sized down by too-tight case mouths/necks. The expander spud/plug should not be more than .0015" smaller than ideal bullet diameter, and some of my revolver spuds are AT BULLET DIAMETER. An appropriate roll crimp into a bullet groove--or a light roll or taper crimp into a bullet sidewall will keep things snugged up. Don't waste a lot of hard work and hobby time just to ruin it with bullet seating into too-small necks and mouths.

One possible benefit that uber-hard alloys might offer is their ability to withstand down-sizing in the under-expanded case necks/mouths of our brass when it is processed in modern die sets--which are largely biased toward the loading of the Red-Coated Pretenders. This assumes that your bullets of whatever hardness were well-fit to the throat(s) of the firearm(s) you are launching them through in the first place. FIT IS KING. Metallurgy & lube/coating won't matter a damn if the bullets don't fit when The Big Light hits them.

And those bullets won't fit if they get sized down by too-tight case mouths/necks. The expander spud/plug should not be more than .0015" smaller than ideal bullet diameter, and some of my revolver spuds are AT BULLET DIAMETER. An appropriate roll crimp into a bullet groove--or a light roll or taper crimp into a bullet sidewall will keep things snugged up. Don't waste a lot of hard work and hobby time just to ruin it with bullet seating into too-small necks and mouths.

Last edited:

Ian

Notorious member

So "splain" to me why, for serious shooting I should anything but RotoMetals Lyman #2 ?

In your case such an explanation would be akin to tilting at windmills.

462

California's Central Coast Amid The Insanity

I'm not a metallurgist, don't know the BHN of any of my bullets, don't shoot high power, don't hunt, don't own an AR, don't do lots of other shooting stuff, but do know that some of my shooting is done with cast bullets softer than Lyman's #2 and the accuracy of those guns is greater than my ability to shoot them, as proven by others who have shot them.